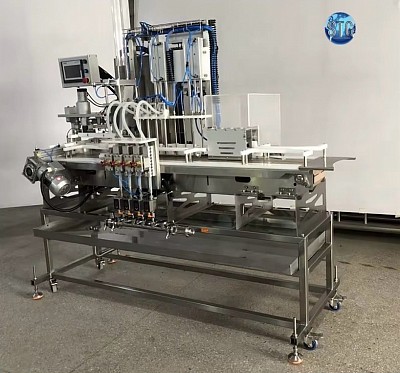

Brewery Equipment

The 4 stations beer can filling machine is an ideal piece of machinery. It is perfect. for small and medium-sized craft breweries or soft drink companies. The machine consists of four main parts: the can rinser, the filler, the lid dropper, and the seamer. The can rinser cleans the cans before filling, using water or air to remove any dust or impurities. The filler fills the cans with beer, using a double pre-evacuation counter pressure filling system that minimizes dissolved oxygen and preserves the flavor and freshness of the beer. The lid dropper places a lid on top of each can after filling, using a sensor probe to detect the fill height and an under lid gassing system to create a protective layer of CO2. The seamer seals the cans with a two roll rotary seamer that ensures a tight and reliable closure. The 4 stations beer can filling machine can process different sizes and formats of cans, ranging from slim 100ml to standard 500ml even 1L, and can handle not only beer, but also carbonated beverages and wine. The machine has a compact design that saves space and is easy to transport. The machine can fill up 15 to 50 CPM depending on the can size and product type. The machine is also easy to operate and clean, with a simple fill speed control, a manual valve manifold, a manual height adjustment system, and a closed CIP circuit. The 4 stations beer can filling machine is an ideal partner for craft beverage makers who want to offer their customers a convenient and attractive packaging option. The machine combines cost-efficient filling technology with high filling quality and flexibility, making it a smart investment for the low and mid output range. Please contact us for machine details.

All Machines Comes With A One Year Warranty.